We want to contribute to a world that provides a viable future with enhanced quality of life for everyone. We do so by creating chemistry for our customers and by making the best use of available resources.

More about sustainability at BASF

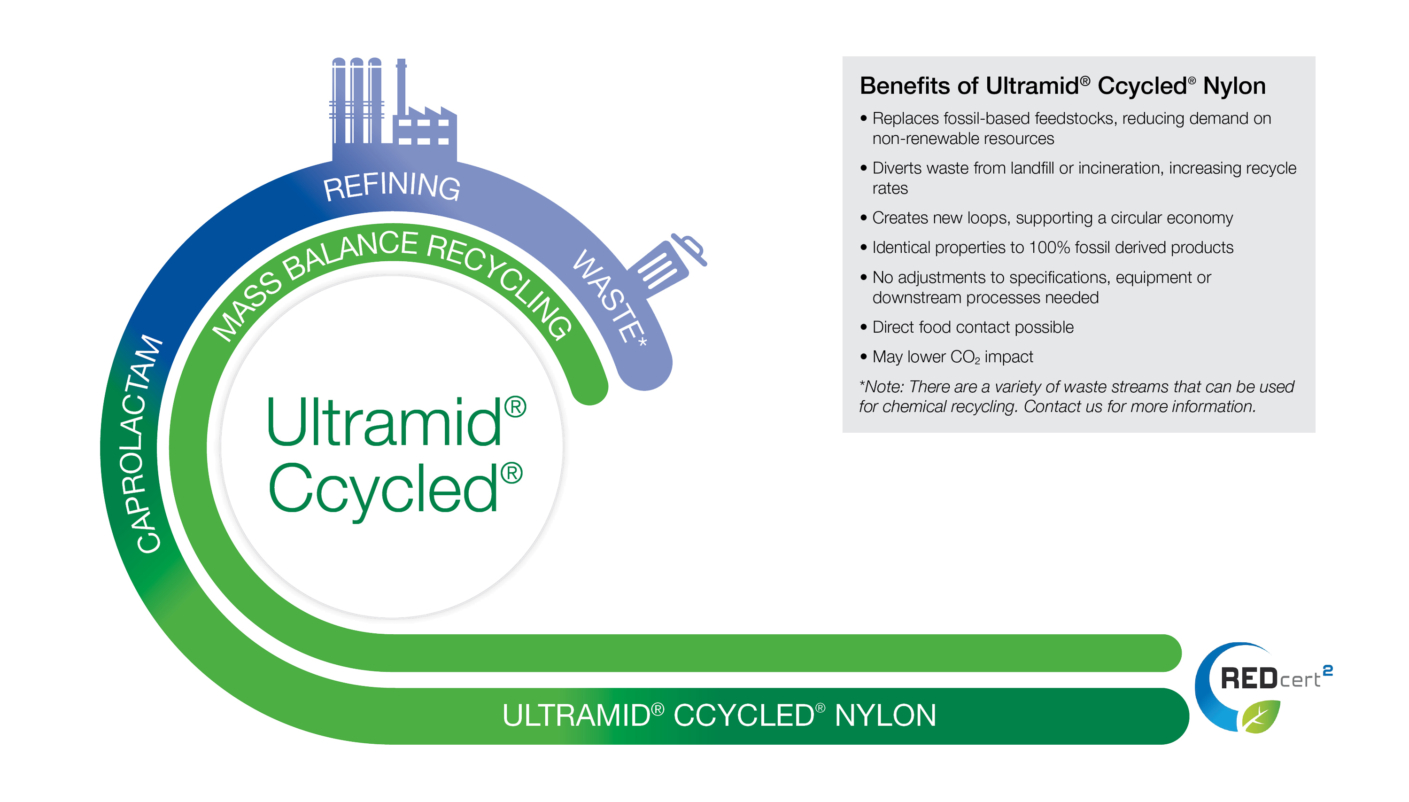

Ultramid® Ccycled™ Nylon: Looking for a recycled nylon for your

application? With multiple pre-consumer and post-consumer feedstock

sources, our Ultramid® Ccycled™ portfolio may be exactly what you're

searching for.

ChemCycling™

Our ChemCycling™ project was initiated by BASF as a pilot in in 2018 to augment mechanical recycling as it's not always a feasible option. Since 2020, our customers have been launching commercial products with Ultramid® Ccycled™ nylons including food packaging.

Mechanical Recycling

BASF is working across the globe to help address issues related to the mechanical recycling of PA/PE multilayer films. Our recent comprehensive study is changing minds about these films and, as a result, they've gained certification by an important institute.

Flex F38

Ultramid® Flex F38 is a novel bio-based nylon copolymer that exhibits performance advantages usually associated with more costly specialty polyamides such as PA6/12, PA11, PA12. Contact us for more information about how Ultramid® Flex F38 fits into your application or click on the link to learn more about the product.

Ultramid® Biomass Balance

Ultramid® Biomass Balance opens up new opportunities to create products with a lower carbon footprint by using certified renewable feedstock to replace fossil resources – all without the need to change your production setup. Without any compromises in quality or performance, you can significantly reduce your GHG emissions. Click on the link to read more or contact us.

Sustainability at BASF

We want to contribute to a world that provides a viable future with enhanced quality of life for everyone. We do so by creating chemistry

for our customers, by making the best use of available resources, and by setting challenging goals such as aiming to achieve net zero CO2 emissions by 2050. Find out more about our goals and solutions.

Our Plastics Journey

The ultimate goal is a circular economy – one in which resources are protected, plastic waste is minimized and the benefits of plastics are

recognized. Join us to discover how we are innovating with our partner organizations to improve how plastics are made, used, and recycled in ways that bring us ever closer to that goal of circularity.

Mass Balance

Mass balance is a chain-of-custody approach to account for materials entering and leaving a system. In the chemical industry, renewable or recycled feedstock is mixed in a continuously operating production process and allocated to the end products after chemical transformations have taken place.